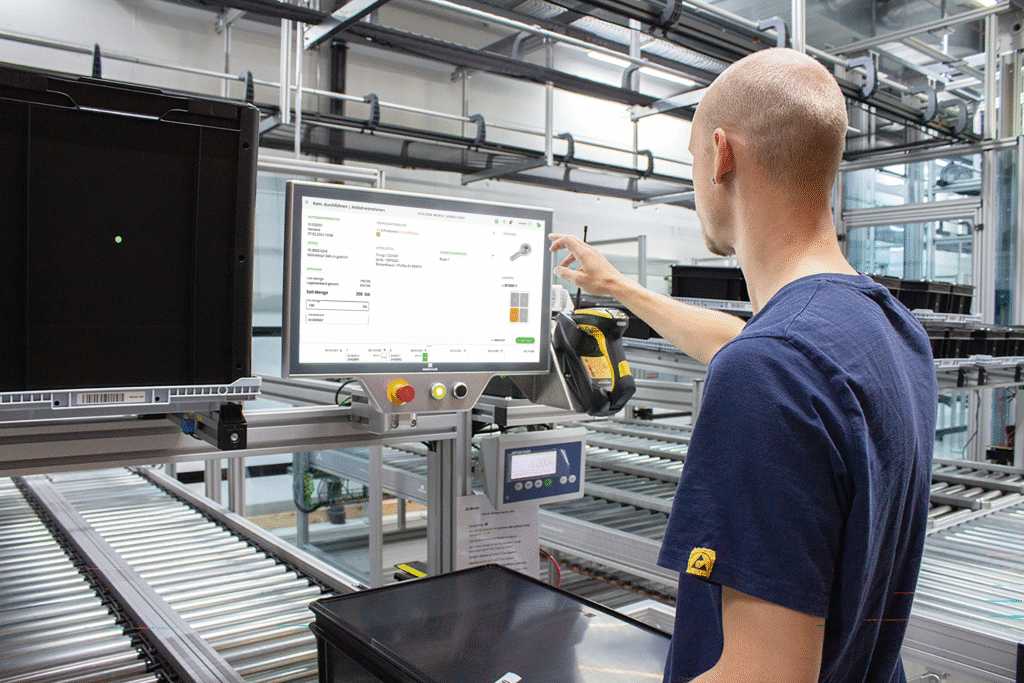

Discover the new Touch 3.0

The next generation of our touch user interface—faster, more intuitive, and more flexible than ever before. The new Touch is the latest generation of our user interface for your warehouse management system. As the central user interface at each station, I-Point Touch seamlessly connects your WMS with the material flows in the warehouse. With version […]

Mentoring for the next generation of entrepreneurs!

In mid-October, our managing director Alexander Fehr had the opportunity to mentor young talents from HTL Dornbirn during Youth Entrepreneurship Week at BSBZ Hohenems. During this project week, 11th-grade students took on an exciting challenge: to develop an innovative solution to a problem and present it to a jury at the end. The initiative inspires […]

MIA Systems participates in reforestation campaign organized by the Lions Club Hohenems

On Saturday, October 4th, our MIA team took part in a wonderful initiative organized by the Lions Club Hohenems. As part of the “Expansion of the Lions Centennial Forest” campaign, around 2,000 young trees were planted in the “Upper Lift” area of Hohenems Schuttannen. With combined efforts and great dedication, we joined numerous volunteers for […]

Team-building rafting adventure: an unforgettable trip on the Bregenzer Ach!

Last weekend, our team took on a very special challenge: an unforgettable rafting adventure on the Bregenzer Ach! In the heart of the Natura 2000 area, High 5 offered us a combination of adrenaline, nature experience and real team spirit. A journey into the wild waters Under the professional guidance of the High 5 team, […]

Hämmerle Kaffee relies on logistics software from MIA Systems

“Authentic enjoyment, top quality and first-class service” – Hämmerle Kaffee GmbH, based in Bludesch, is investing in the expansion and digitalization of its logistics center. The long-established company relies on the Warehouse Management System (WMS) from MIA Systems for warehouse management. Hämmerle Kaffee GmbH is a wholesaler, manufacturer of instant hot drinks, specialist for coffee […]

KVP Days at Hirschmann Automotive in the Czech Republic

Together with Servus Intralogistics, MIA Systems was involved in the digitalization and automation of our customer Hirschmann Automotive at the Vsetín site in the Czech Republic. One year after the go-live, a KVP meeting with the entire project team took place on site last week. Hirschmann Automotive relied on the smart production concept for the […]

Industrial UX Design: We are shaping the future of intralogistics

Digitalization and automation present companies with major challenges. Automated small parts warehouses, driverless transport systems, cloud software, business intelligence and the ongoing optimization of logistics processes are the new standard. However, user-friendliness and user interfaces are often neglected, especially with this high investment volume. This results in falling productivity and low employee acceptance, high training […]

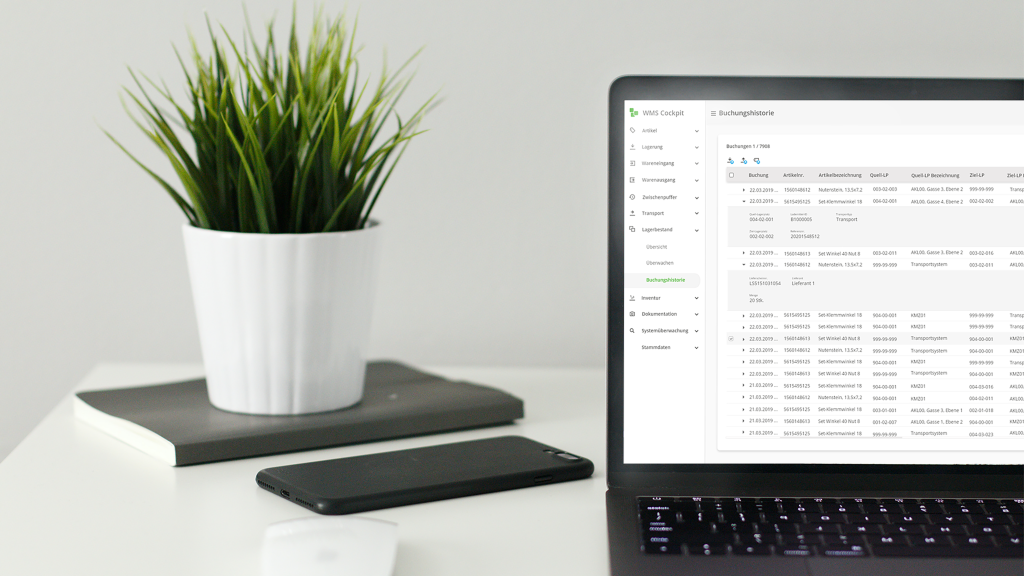

Booking history: Display and evaluate warehouse bookings with high performance

Warehouse movements in the WMS generate very large amounts of data – every single stock change, every movement and every transport is recorded. The smart data storage in the MIA WMS nevertheless enables you to access this data quickly and evaluate this treasure trove of data. This data is displayed transparently and with high performance […]

Photo documentation: Record the condition of the delivery with the mobile scanner

With MIA Mobile, you can easily photograph and document the condition of your goods and shipments – directly in your mobile processes – with an integrated camera in the mobile scanner. You can access this image material in MIA Cockpit and have the option of downloading it for further processing. Simple, integrated into the processes […]

Kral GmbH: Winner of the Austrian Logistics Award 2020

Congratulations to our customer KRAL GmbH on winning the Austrian Logistics Award 2020! We are delighted to be part of this successful regional project with our Warehouse Management System (WMS). The decisive factor for the “Digitalization and automation in production and logistics” project was to shorten the lead time in production in order to improve […]