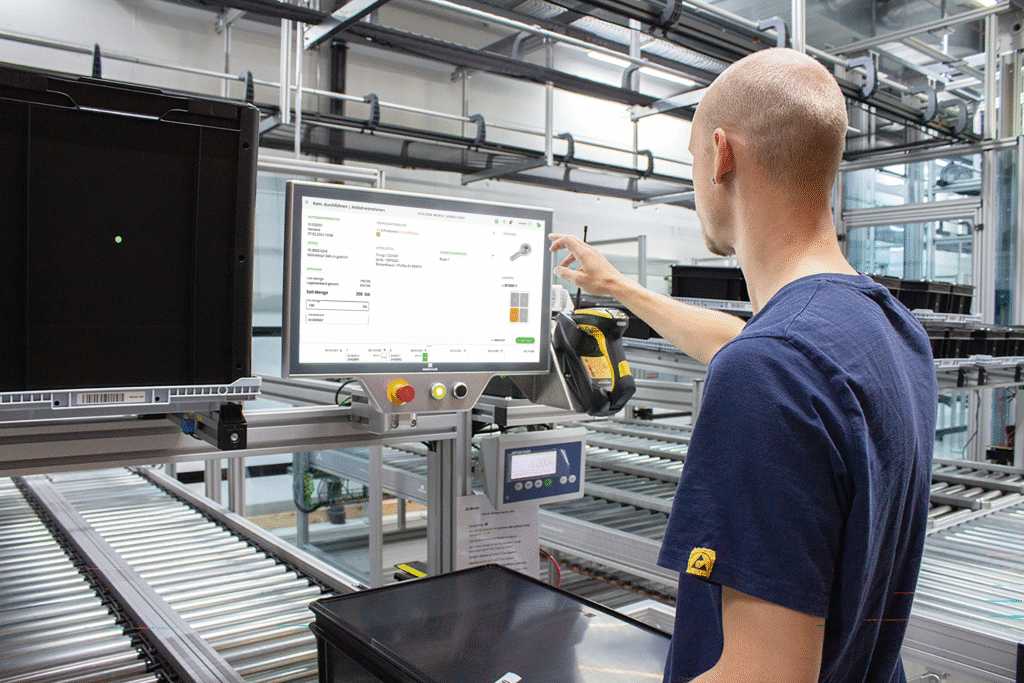

Discover the new Touch 3.0

The next generation of our touch user interface—faster, more intuitive, and more flexible than ever before. The new Touch is the latest generation of our user interface for your warehouse management system. As the central user interface at each station, I-Point Touch seamlessly connects your WMS with the material flows in the warehouse. With version […]

“I’m coming along” – Future Day at MIA Systems

Last Thursday, we had some special visitors at MIA Systems: Jonas, Jodok, and Leopold joined us as part of Vorarlberg’s Future Day “Ich geh mit” (I’m coming along) and experienced firsthand how diverse and exciting the world of software development can be. Get in, discover, participate We started with a short tour of the company: […]

Hämmerle Kaffee relies on logistics software from MIA Systems

“Authentic enjoyment, top quality and first-class service” – Hämmerle Kaffee GmbH, based in Bludesch, is investing in the expansion and digitalization of its logistics center. The long-established company relies on the Warehouse Management System (WMS) from MIA Systems for warehouse management. Hämmerle Kaffee GmbH is a wholesaler, manufacturer of instant hot drinks, specialist for coffee […]

KVP Days at Hirschmann Automotive in the Czech Republic

Together with Servus Intralogistics, MIA Systems was involved in the digitalization and automation of our customer Hirschmann Automotive at the Vsetín site in the Czech Republic. One year after the go-live, a KVP meeting with the entire project team took place on site last week. Hirschmann Automotive relied on the smart production concept for the […]

Industrial UX Design: We are shaping the future of intralogistics

Digitalization and automation present companies with major challenges. Automated small parts warehouses, driverless transport systems, cloud software, business intelligence and the ongoing optimization of logistics processes are the new standard. However, user-friendliness and user interfaces are often neglected, especially with this high investment volume. This results in falling productivity and low employee acceptance, high training […]

Kral GmbH: Winner of the Austrian Logistics Award 2020

Congratulations to our customer KRAL GmbH on winning the Austrian Logistics Award 2020! We are delighted to be part of this successful regional project with our Warehouse Management System (WMS). The decisive factor for the “Digitalization and automation in production and logistics” project was to shorten the lead time in production in order to improve […]

MIA realizes “Hands-Free Picking” with ProGlove

“Mark” is the name of the intelligent glove from the innovative Munich-based start-up ProGlove, which makes work faster, safer and more ergonomic. The glove with built-in sensors and scanner adapts perfectly to the worker’s natural hand movements, thus enabling “hands-free picking”. This means that the worker does not need to reach for the scanning gun, […]

Efficient picking through multi-order picking

Our customer, Hasler + Co AG in Winterthur, uses the multi-order picking process. With this picking method, several customer orders are processed at the same time. This results in shorter walking distances for employees, faster throughput times and consequently a reduction in order processing costs. The employees in the warehouse are supported by our web-based […]