MIA I-Point Touch – Intelligent control directly at the station

Each station in your automated transport system is equipped with a touch terminal – the MIA I-Point Touch. This intelligent control center seamlessly connects your MIA Warehouse Management System (WMS) with the transport processes and ensures efficient control and data collection in real time.

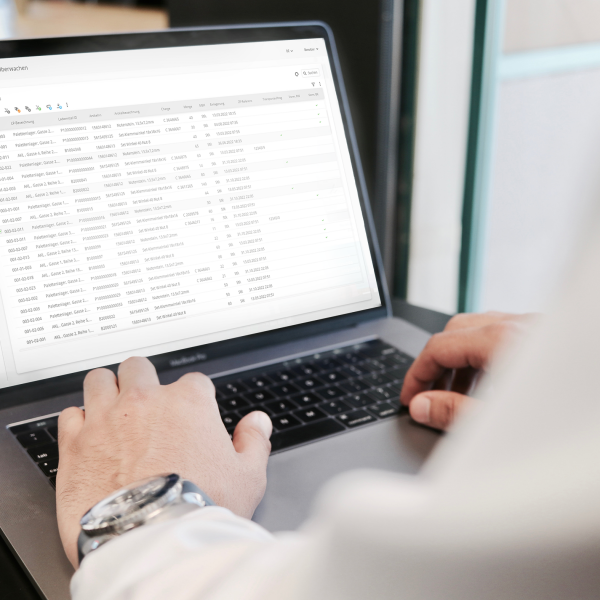

Maximum efficiency through smart extensions

The MIA I-Point Touch can be optionally equipped with a barcode scanner or RFID reader to record inventory and goods movements even faster and more accurately. This ensures that transport processes are handled without errors and significantly optimizes your warehouse logistics.

The central access point for all logistics processes

From incoming goods to intermediate buffers to order picking, the MIA I-Point touch terminal offers direct access to all relevant warehouse processes. Thanks to its intuitive design and clear process guidance, employees are visually guided through each step of the process—efficiently, safely, and error-free.

Your advantages at a glance:

- Seamless communication between MIA WMS & transport system

- Optional extension with barcode & RFID technology

- Real-time data acquisition for error-free processes